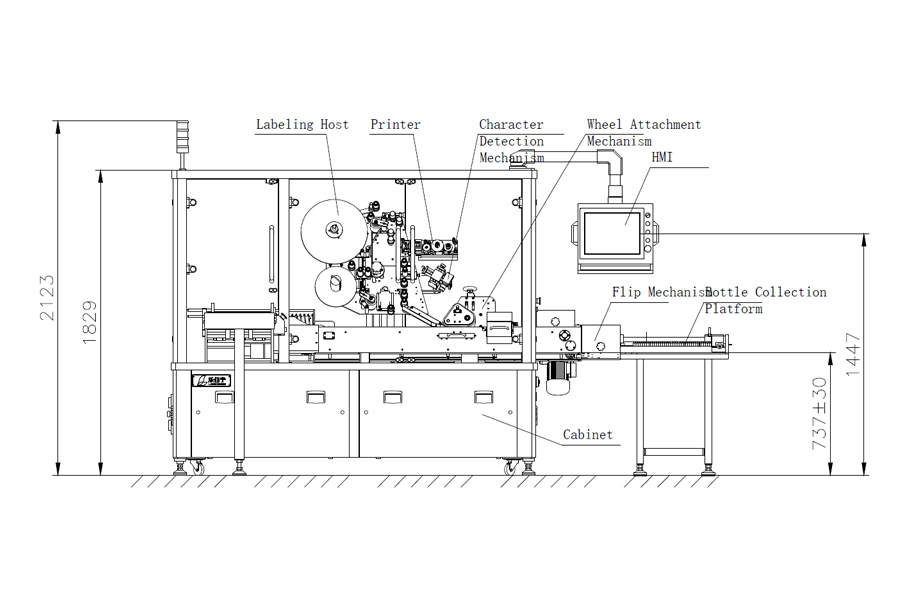

Maximize accuracy and speed in your pharmaceutical packaging line

Pharmaceutical ampoules come in different sizes, materials, and formats. The labeling machine must adapt without tool changes or production delays.

At PharmaLabeler, our automatic systems support:

-

1ml – 20ml glass ampoules (commonly used in injections)

-

Diameter 10-24mm or 16-30mm

-

Vials and mini bottles used in ophthalmology or vaccine packaging

-Why Fully Automatic Labeling Is the Smart Choice

In modern pharmaceutical production, speed, accuracy, and reliability are non-negotiable.

That’s why fully automatic labeling machines are the industry standard — especially when you need:

-

High throughput (up to 42,000 ampoules/hour)

-

Consistent label application under sterile conditions

-

Reduced human error and contamination risk

-

Smooth integration with upstream and downstream systems

PharmaLabeler specializes in fully automatic labeling systems — engineered for 24/7 operation and validated GMP environments.

-Key Features You Should Look For

Choosing the right machine is about more than speed — it's about fit and flexibility.

Here are 5 features to prioritize:

-

Servo-Driven Label Feed – ensures consistent label placement

-

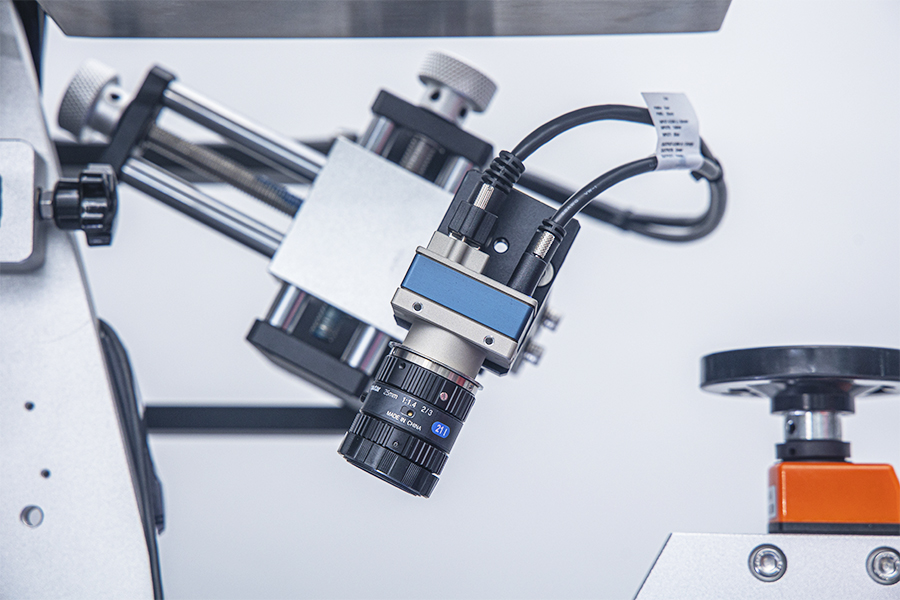

Vision Inspection System – detects misaligned or missing labels

-

Reject & Sorting Station – automatically removes defective ampoules

-

Compact Modular Design – integrates easily with tray loaders/cartoners

-

GAMP/GMP-Compliant Construction – stainless steel frame, validated documentation

-After-Sales Support & Global Deployment

From remote configuration to rapid spare parts delivery, our team ensures your machine stays running — and compliant.

✅ English language support

✅ Fast-response video troubleshooting

✅ Full FAT/SAT/DQ/IQ/OQ documentation

✅ CE certified

Looking for a reliable ampoule labeling solution?

Get a customized quote based on your ampoule size, tray style, and speed requirements. WhatsApp: 008615895568335