Powering Pharmaceutical Production in Uzbekistan: LEBONING Delivers Advanced Glass Ampoule and BFS Labeling Solutions

We’re excited to share that our team is currently manufacturing three advanced labeling machines for a valued pharmaceutical client in Uzbekistan! These high-precision machines are being custom-built to meet their specific production needs and will soon enhance their packaging line efficiency.

This project showcases our expertise in handling delicate products like glass ampoules and specialized formats like Blow-Fill-Seal (BFS) containers, integrating essential quality control features like printing and vision inspection.

Tailored Labeling Solutions for Ampoules and BFS Containers

1. Ampoule Labeling Machine with Tray Separation & Inserting System (Model Y-510)

Quantity: 2 unitsKey Features:

First Unit: Designed for 2ml and 5ml glass ampoules

Second Unit: Compatible with 2ml, 5ml, and 10ml glass ampoules

Tray handling: Automatic separation and inserting system

Printing & Inspection:

-Integrated inkjet printer for on-label variable data printing

-Camera inspection + industrial PC for real-time print verification

High precision: Ensures accurate label placement every time

[Client-Specific Product Application]

Ampoules and Tray dimensions:

| NO | Specification | Diameter | Tray Size L*W*H (mm) |

| 1 | 2ml | φ11.5mm | 74.5*73*12 |

| 2 | 5ml | φ16mm | 102*85*17 |

| 3 | 10ml | φ18.4mm |

124*105*19 |

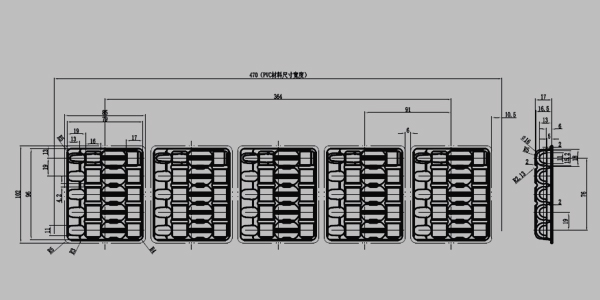

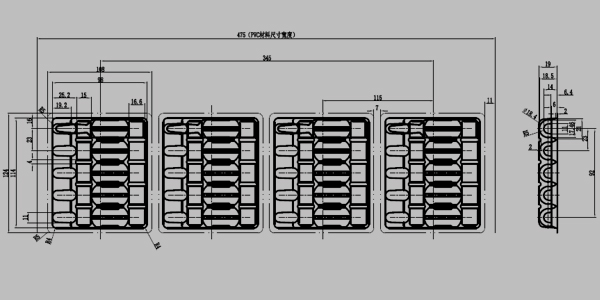

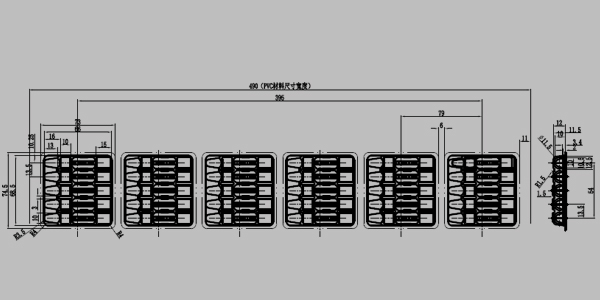

Tray Drawings:

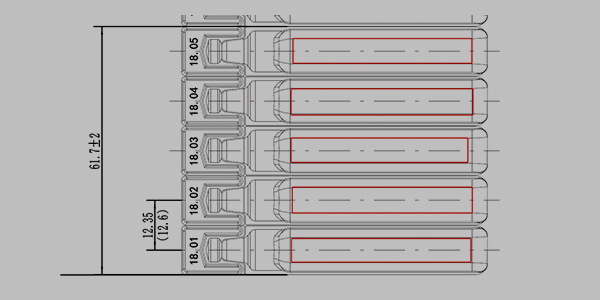

2. BFS Labeling Machine for Plastic Ampoules (5-Label Application)

Quantity: 1 unitAdvanced Capabilities:

-Designed for single-use plastic ampoules (BFS containers)

-Five-label simultaneous application for high efficiency

Speed: Up to 100 panels per minute

Printing Technology:

Thermal transfer printing for durable, high-quality codes

Vision Inspection:

Integrated camera system to verify print and label accuracy

Seamless Integration:

-Connects with vision inspection machines

-Adjustable conveyor height (930mm ±30mm) for flexible production line setup

[Client-Specific Product Application]

Why Global Pharma Manufacturers Trust Our Labeling Machines

This order reinforces key strengths of our labeling solutions:✅ Flexibility – Handles multiple container sizes (2ml to 10ml) and materials (glass & plastic)

✅ Smart Printing Options – Inkjet + thermal transfer for variable data and barcode needs

✅ Zero Defects Guarantee – Vision inspection ensures 100% labeling accuracy

✅ High-Speed Performance – Optimized for large-scale production demands

✅ Plug-and-Play Integration – Designed to connect with existing packaging lines

Next Steps: Installation & Training

Once production is complete, our team will:

✔ Conduct factory acceptance testing (FAT) to ensure flawless performance

✔ Provide on-site installation & commissioning support

✔ Deliver operator training for smooth machine operation

Interested in a Custom Labeling Solution for Your Production Line?

Our team specializes in tailored pharmaceutical labeling machines for ampoules, vials, BFS containers, and more.

Contact us today for a consultation!Whatsapp:0086 15895568335