BENEFITS OF PHARMACEUTICAL LABELING MACHINE

High Precision Labeling

Utilizes advanced sensor technology to ensure accurate label placement on bottles, vials, and packages.

Maintains consistent labeling quality even at high production speeds.

Reduces label misalignment, which is critical for pharmaceutical compliance.

Maintains consistent labeling quality even at high production speeds.

Reduces label misalignment, which is critical for pharmaceutical compliance.

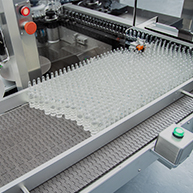

Efficiency and Speed

Capable of labeling hundreds to thousands of units per hour, increasing production output.

Automated label application minimizes manual labor and reduces human errors.

Works smoothly and quietly, ensuring a better production environment.

Automated label application minimizes manual labor and reduces human errors.

Works smoothly and quietly, ensuring a better production environment.

Heat Resistance & Durability

Designed to withstand high-temperature environments, such as sterilization lines or hot-fill packaging processes.

Uses heat-resistant materials to ensure stable operation under extreme conditions.

Components maintain performance even after prolonged exposure to high-temperature settings.

Uses heat-resistant materials to ensure stable operation under extreme conditions.

Components maintain performance even after prolonged exposure to high-temperature settings.

Regulatory Compliance & Safety

Ensures compliance with FDA, GMP, and other pharmaceutical labeling regulations.

Equipped with automatic error detection, stopping the process when incorrect or missing labels are detected.

Audible alarm system alerts operators if an issue occurs, ensuring labeling accuracy.

Equipped with automatic error detection, stopping the process when incorrect or missing labels are detected.

Audible alarm system alerts operators if an issue occurs, ensuring labeling accuracy.

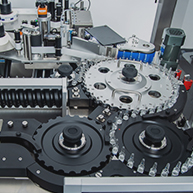

Versatile Labeling Capabilities

Supports various container shapes (round, square, flat, or irregular).

Compatible with different label materials, including paper, plastic, and RFID tags.

Can apply labels to both primary (bottles, ampoules) and secondary (cartons, boxes) packaging.

Compatible with different label materials, including paper, plastic, and RFID tags.

Can apply labels to both primary (bottles, ampoules) and secondary (cartons, boxes) packaging.

Cost-Effective & Reduced Waste

Minimizes label wastage by using precise application technology.

Reduces production downtime with fast changeover capabilities for different label sizes and products.

Long lifespan of components lowers maintenance costs.

Reduces production downtime with fast changeover capabilities for different label sizes and products.

Long lifespan of components lowers maintenance costs.